Rear Axle Assemblies

Rear Axle components are critical in maintaining strength and longevity against the demand the engine, driveline and chassis puts on them. The more power an engine makes the stronger each axle component has to be. Selecting the correct axle ratio is one of the most important selections in implementing power the engine creates through the chassis and to the tire. If the wrong axle ratio is installed for a given power/rpm band this could impair the cars acceleration and performance capabilities drastically.

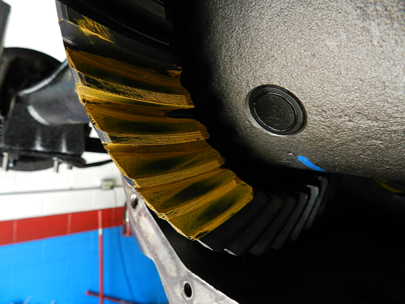

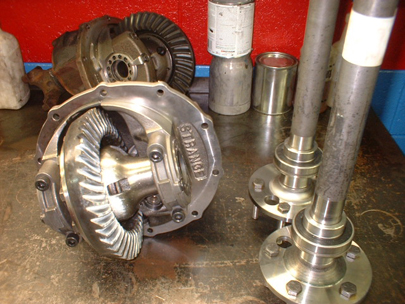

Ring gear installation is critical and the correct process for installing them is often overlooked. After we achieve the necessary adjustments and settings, we verify the run mesh pattern with lead grease, which we applied on the teeth of the ring and pinion gears. This method gives a visual mesh pattern assisting us in making sure the contact mesh points on both sides of each tooth are correct as they were manufactured from the manufacturer, otherwise without verification premature gear wear can accrue creating an expensive lesson.

Properly installing a gear set can be very time consuming even for us if there is an axle housing issue. An axle housing issue can be inherited from the manufacture when it was first made, or if the housing was damaged, say bent in some way, in most cases a correct install can be still be achieved if issues are small. An easy and quick way to verify an issue at the start is when the axles were removed from the housing. A stubborn axle removal/install is a sign that an axle tube is bent, two stubborn axles is a sign the house is sprung and the outter axle axle bearings are not in line with the inner center carrier bearings. In this case straightening the housing is required, and a possibly along with straightening the bearing ends on the ends of the axle tubes need repositioned. Another issue is when the center lines of the carrier bearing bores are out of position with the pinion gear’s depth, this correction is normally made with the pininon's position if possible. This type of issue you will find during the installation process when the proper pinion gear depth position is out of position beyond the adjustability range machined into the axle housing case. When adding or removing pinion shims don’t correct this issue enough you are better off replacing the complete axle housing. Any one of these issues can create a poor installation and create premature gear failure if undetected and serviced.

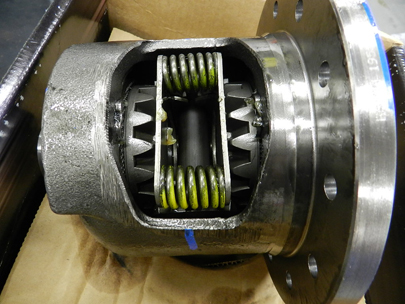

The 3 or 4 series deferential carriers are common in the early performance cars mostly due to the 3-4 series gear ratio selected and or installed at the factory, so many early carriers support the dual clutch pack systems (Limited Slip Differential). There are many different deferential carrier styles used today, some are clutch pack (Limited Slip), slip friction resistant, cone type and the locker, so selection can be confusing to the novice, while making the decision, consider strength as your number one concern. For all out drag racing there’s the spool carrier, which does not allow the wheels to turn at different rates under power and or while turning the car, the tire slips on the ground to achieve that.

Along with choosing axles, axle diameter and increased spline count is what's required for high power cars with good traction capabilities. Spline counts can range from 27 to 40 splines, as the spline count increases the axle diameter normally does as well. Over sizing an axle diameter for a lower HP engine the heaver axles increases the rotating mass of the axle therefore eating up your power. Larger splined axles with smaller diameter axle’s shafts will allow the axle to twist more and not twist the splines, but keep in mind this is for lower power engines and or low traction capability suspensions. In a high powered car the shorter the axle is the bigger the chance the splines will twist when the tire is in full contact on the ground say using a large slick, so more spline count and diameter is important related to strength. Another important related issue to longevity should always be at the top of your list, install all the axle shaft bearings and seals, carrier bearings and pinion bearings and seal new, or seek out a professional to help you.

Axle shaft screw-in wheel studs are a must with bolt-in axles; C clip style retained axles are a bad choice when it comes to hard core racing. Bolt-on axle bearing retaining plates at the brake backing plates replace the internal differential C-clip retainer, improving support that the axle shafts won’t come out of the axle housing during operation.

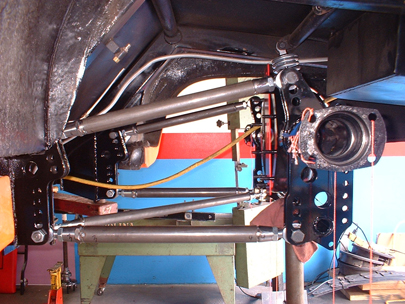

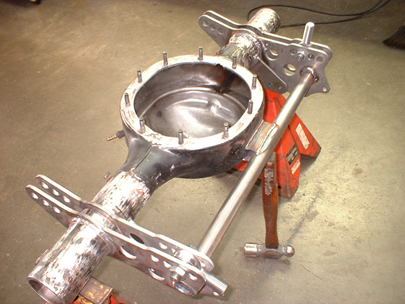

Many options are available for the axle housing, the Ford 9" is the most popular for power producing cars with a good chassis and traction control. Narrowed with 4 Link bars and gussets make housings like this super strong, while adding strength support brackets improve their strength even more from flexing and changing the mesh settings on the ring and pinion gears and preload on the carrier bearings.